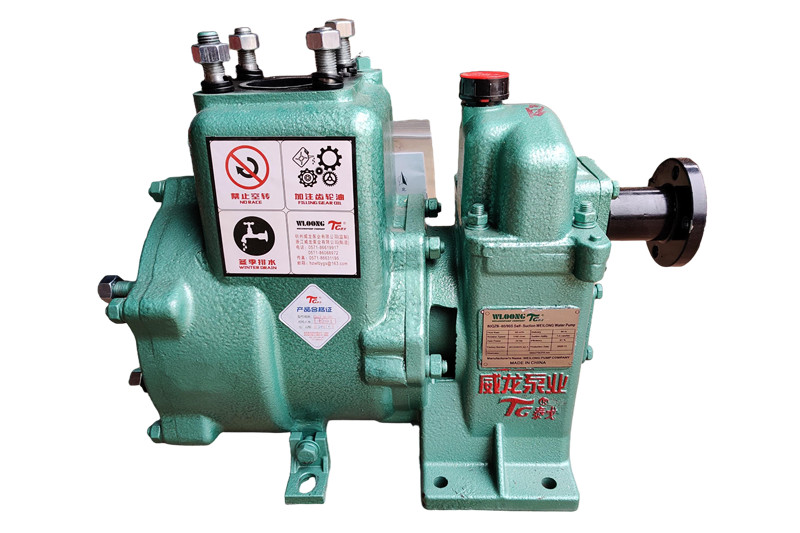

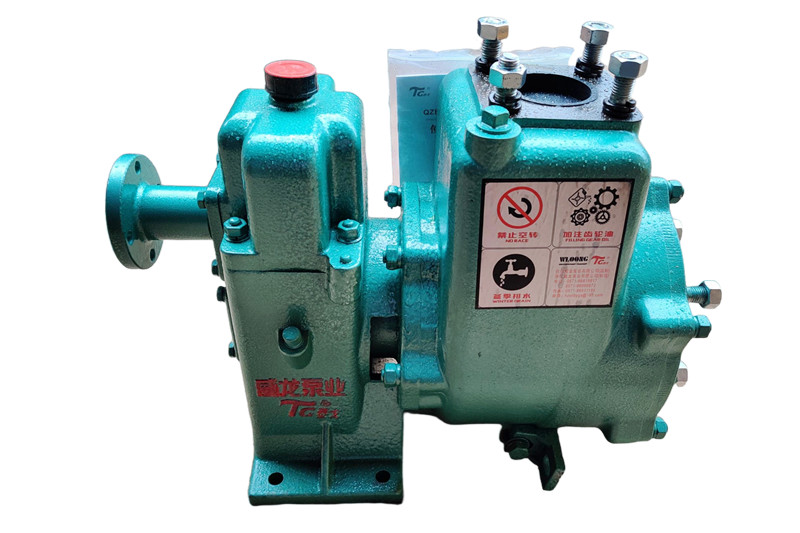

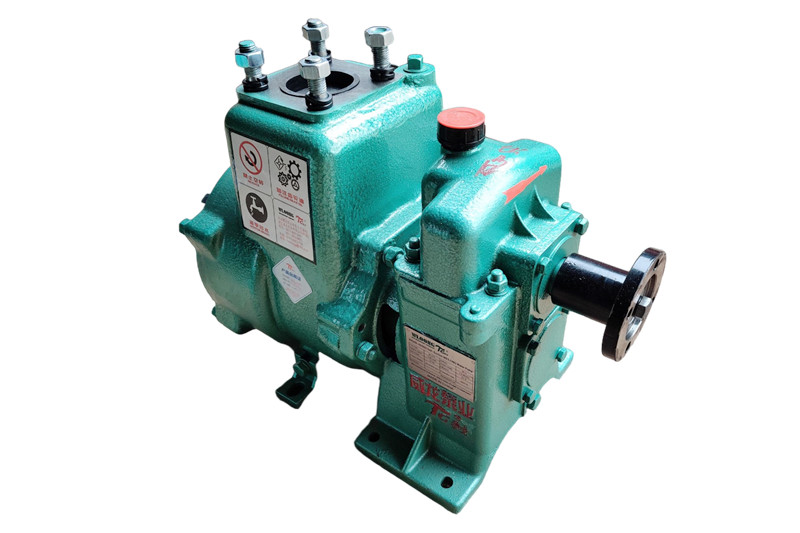

80QZF-6090SÕ×ŗµ░┤µ│Ąµś»õĖƵ¼ŠõĖōõĖ║µ┤Ƶ░┤ĶĮ”ÕÅŖÕģČõ╗¢õĖōńö©ĶĮ”ĶŠåĶ«ŠĶ«ĪńÜäĶć¬ÕÉĖÕ╝Åń”╗Õ┐āµ│ĄŃĆéÕģȵĀĖÕ┐āÕÅéµĢ░Õīģµŗ¼’╝ܵĄüķćÅ60 m┬│/h’╝īµē¼ń©ŗ90 m’╝īĶć¬ÕÉĖķ½śÕ║”6.5 m’╝īĶć¬ÕÉĖµŚČķŚ┤1.5 minŃĆéĶ»źµ│Ąķććńö©ķōĖķōüµØÉĶ┤©’╝īÕģʵ£ēÕż¢µĘĘÕ╝ÅĶć¬ÕÉĖń╗ōµ×äŃĆéńö▒ĶĮ”ĶŠåÕŖ©ÕŖøĶŠōÕć║ĶĮ┤ķ®▒ÕŖ©’╝īķĆéńö©õ║ÄĶŠōķĆüµĖģµ░┤õ╗ŗĶ┤©ŃĆé

The water pump features a speed-increasing gearbox design, consisting of a pump body, impeller, mechanical seal, and other components. It eliminates the need for a foot valve in the suction line, resulting in a compact structure and convenient operation and maintenance.

┬╗. Working Principle of 80QZF-6090S Water Pump:

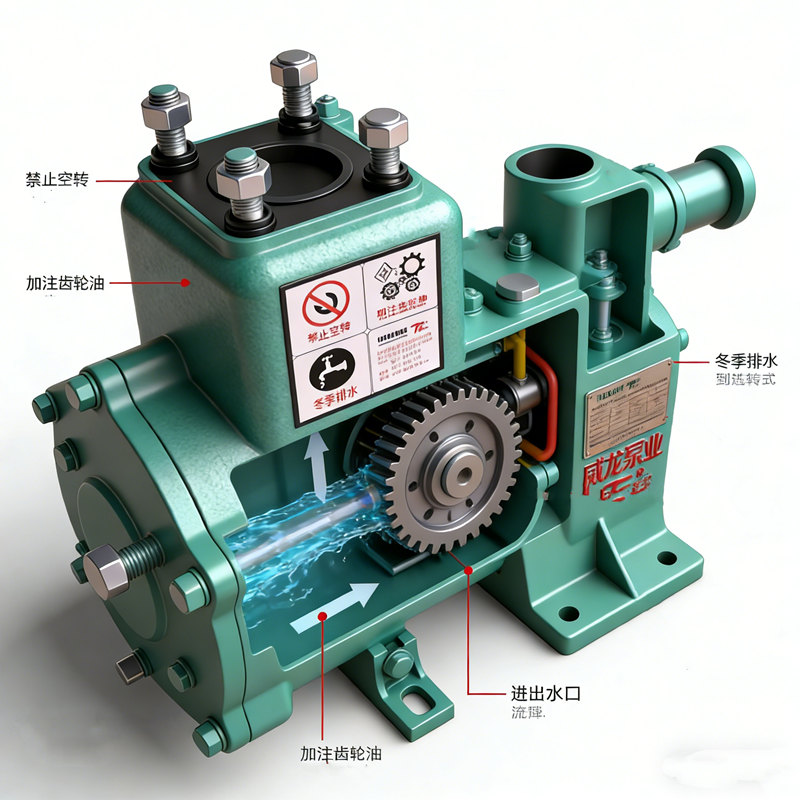

ŌŚÅ This type of pump adopts an external mixing axial return pump body structure. The pump body consists of a suction chamber, a liquid storage chamber, a return orifice, and a gas-liquid separation chamber.

ŌŚÅ After the pump starts, the impeller draws in the liquid stored in the pump body and the air in the pipeline, which are then completely mixed within the impeller. Under centrifugal force, the mixed liquid enters the gas-liquid separation chamber through the discharge chamber.

┬╗. Structural features

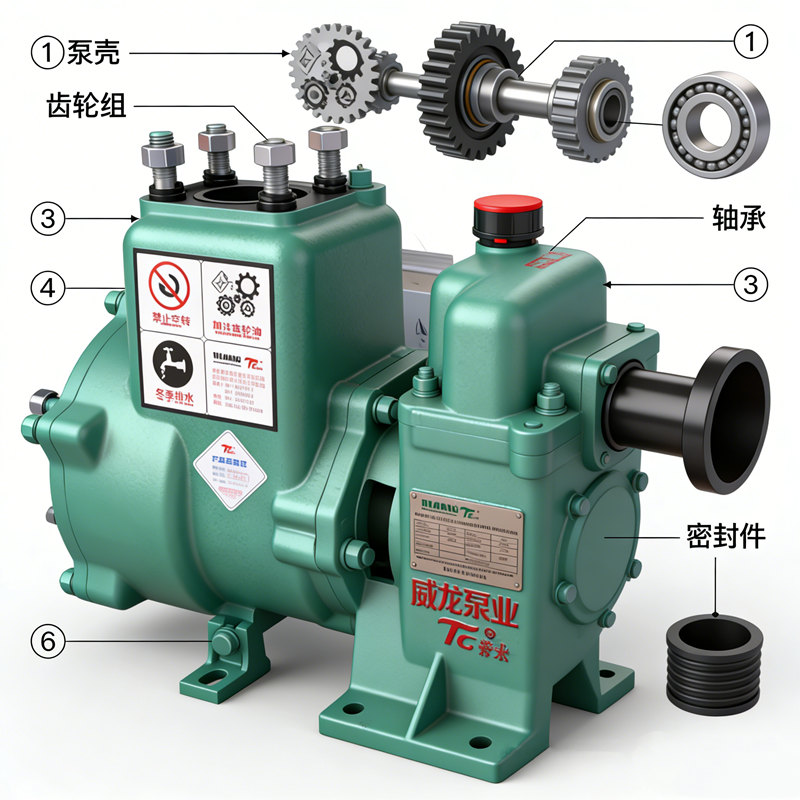

1. This series of pumps is a self-priming centrifugal pump with a speed increaser, mainly composed of a pump body, impeller, mechanical seal, shaft, and speed increaser.

2. The power required for pump operation is directly provided by the vehicle engine through a power take-off (PTO).

3. A foot valve is not required on the pump's suction line. It features a compact structure, convenient operation and maintenance, and high efficiency. The suction pipe inlet should be placed inside a mesh cover; the total area of ŌĆŗŌĆŗthe mesh cover's through holes should be greater than 300 cm┬▓, and the mesh diameter should be less than 6 mm.

4. The pump's shaft seal uses a mechanical seal, ensuring reliable operation and a long service life.

┬╗. Maintenance and Care:

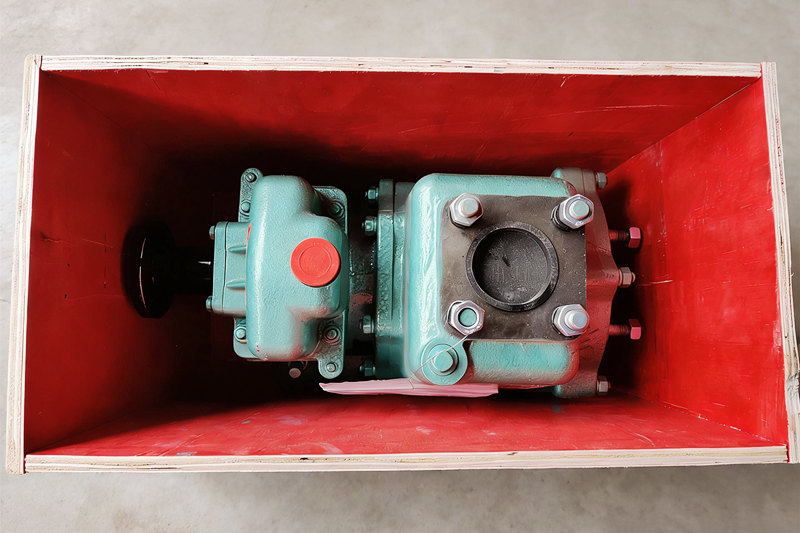

1. The bearings and gears in the pump speed increaser are lubricated by injecting gear oil. Before use, the user should check the dipstick to ensure the oil level is within the standard range. If not, add or drain gear oil.

2. Before operating the pump, check that the pump reservoir is full. If insufficient, add more reservoir. Do not operate the pump without sufficient fluid to avoid damaging the mechanical seal. Open the valves on the suction and output lines.

3. Strictly inspect the installation of the suction line. No air leaks are allowed in the suction line; otherwise, self-priming will fail.

4. Check that the rotation direction is correct.

5. If strong vibration and noise occur during pump operation, it may be due to cavitation. Cavitation is mainly caused by excessive flow rate or too high suction head.

6. When the pump stops working, first gradually close the output pipeline control valve, and then stop the prime mover.

Ō¢Č . Special Reminders :

Ō׿ Before operating the pump, it must be filled with priming water; otherwise, damage to the mechanical seal will cause leakage.

Ō׿ When the temperature is below zero degrees Celsius, after operation, the water inside the pump must be drained; otherwise, the pump housing may burst due to freezing.

Ō׿ When the water source contains mud, sand, or long fibrous debris, take precautions to prevent it from being sucked into the pump, which could damage the mechanical seal and impeller.

Ō׿ If no water is output within 2 minutes of starting the pump within the normal self-priming height, please stop the machine immediately and check!

µĀćńŁŠ :